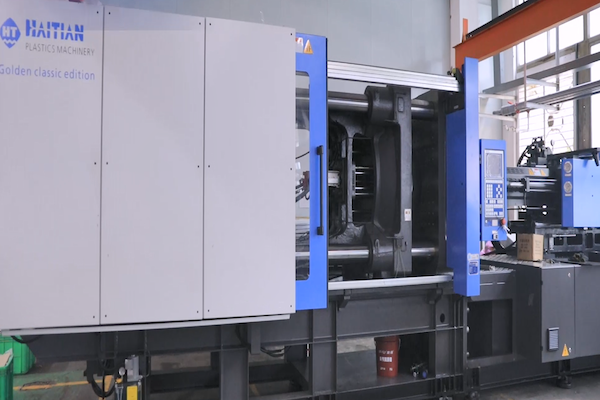

1. High efficiency of injection molding machines

Our injection molding workshop is equipped with advanced injection molding machines, which can achieve 24-hour uninterrupted production, greatly improving production efficiency. The automated operation of the injection molding machine reduces manual intervention, ensures product consistency and quality stability, and also reduces the risk of human operation errors.

2. Accurate supply of automatic raw material conveying equipment

Automatic raw material conveying equipment ensures the timely and accurate supply of raw materials in injection molding production. This system can automatically weigh and convey raw materials, reduce the labor intensity and material waste of manual handling, and also improve the accuracy of material ratio, ensuring the stability and reliability of the product.

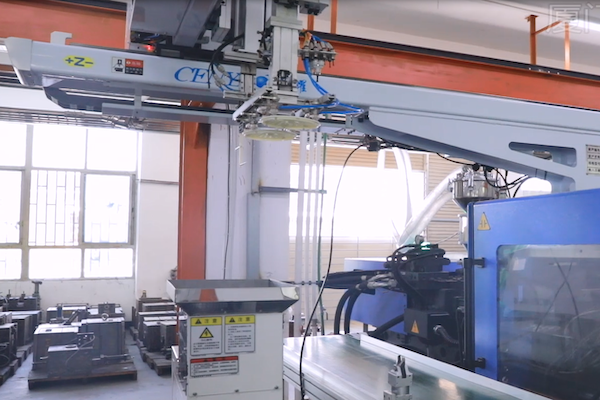

3. Efficient post-processing of automatic gate cutting equipment

After the injection molding of the injection molded parts, the automatic gate cutting equipment can quickly and accurately cut off the gate. This process does not require manual operation, which greatly improves the efficiency of post-processing. Automated shearing not only increases production speed, but also reduces the product damage rate caused by improper human operation and improves the product yield rate.

4. Resource recycling of automatic crushing equipment

Our workshop is also equipped with automatic crushing equipment to crush unqualified products and waste materials in production for recycling and reuse. This equipment not only improves the efficiency of waste treatment, but also helps to achieve the recycling of materials and reduce environmental pollution, reflecting the company's environmental responsibility and sustainable development concept.