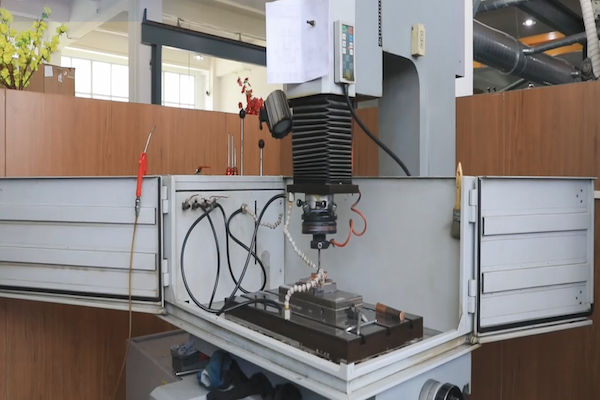

Our mold machining workshop has a strong R&D team, equipped with multiple high-precision EDM machines, Grinding machines and NC equipment. This not only reflects our emphasis on technological innovation, but also ensures that we can quickly respond to market changes and meet customer needs.

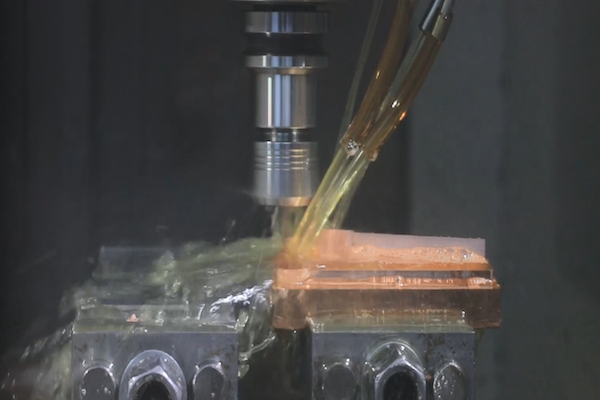

1. High-precision EDM machine

The application of EDM machines has significantly improved the efficiency of mold processing. Compared with traditional mechanical processing, EDM can quickly remove metal, especially when processing carbide or other difficult-to-process materials, showing incomparable superiority, greatly shortening the production cycle of the mold and ensuring the high quality standards of the mold. By precisely controlling the discharge parameters, our equipment can achieve fine processing of the mold surface, thereby improving the surface finish and service life of the mold, and meeting the strict requirements of bathroom products for mold precision.

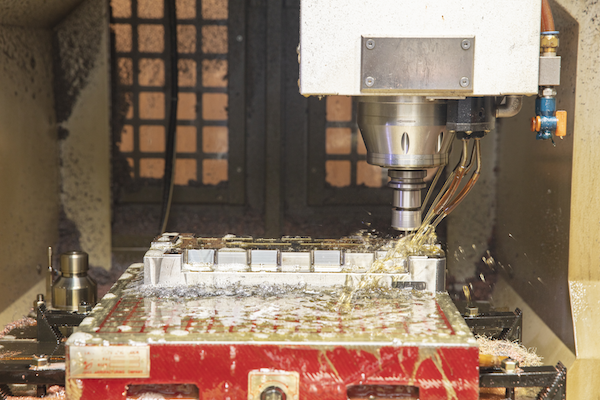

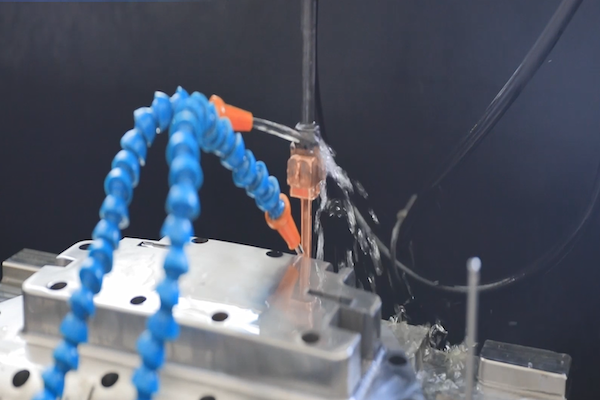

2. Technical advantages of NC equipment

Through the efficient processing capabilities of NC equipment, we can reduce the waste of raw materials and labor costs in the mold manufacturing process, thereby effectively reducing production costs. At the same time, we can quickly adjust equipment parameters to adapt to the design requirements of different molds, shorten the production cycle of molds, and quickly respond to market changes and customer needs, speeding up the time to market.